PilingLock System

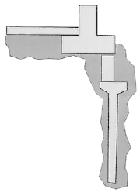

Mississippi Foundation Repair's PilingLock System consist of

Pilings That Truly Lock Together!

This complete System is comprised of a triangular piling to prevent upheaval, 7000 psi pre-cast concrete cylinder

pilings with concentric channel, all metal components are completely non-corrosive and torqued down to meet or

exeed building strength requirements. Once the system is completed all pilings are securely locked together

to become a single support unit. Once the system is locked, it forms a continous non-corrosive metal rod which

will not bend nor flex, as can occur with cables or other methods.

Piling Lock Step by Step Process

Step 1 -

SITE PREPARATION: Mississippi Foundation Repair Specialists' crew prepare the site

prior to excavation by relocating any plants from the work area. Access holes will then be dug by hand to a

depth of three to four feet. Since the holes are approximately the size of a door mat, MFRS covers each hole

with a heavy piece of plywood for your safety. No holes or access shafts will be cut inside your home, unless

interior pilings are required to support your foundation.

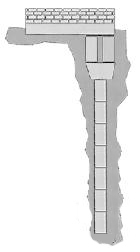

Step 2 -

DRIVING THE PILINGS: Since we will require the use of several electrical outlets each on a separate

circuit, MFRS will need access to the interior of your building.

Rod-anchors are pressed into the ground at specific locations along and/or within the foundation, then piling cylinders are added(connecting rods running through the center of each). Each piling is driven to the required depth.

Finally, MFRS installs a cap atop the last piling segement and the rods are

LOCKED into place.

Concrete blocks are positioned between the cap, directly under the bottom of the foundatin beam.

Once the system is completed, all pilings are locked together and become a single, stable support unit.

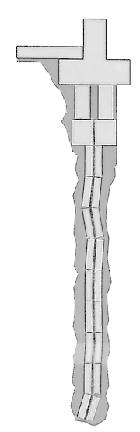

Step 3 -

SUPPORT YOUR STRUCTURE: Once the MFRS Piling Lock System is installed, one of our certified

technicians supervises the support process, monitoring your home's reaction to the process. Once the

support is finished, spaces are placed on the concrete blocks to support the building.

The tops of all holes are refilled with soil, concrete breakthroughs are patched, and plants are replanted. All walks

and driveways are cleaned.

This Three-Step process usually takes from one to three days, weather permitting.

All piling Materials, Rod, Bolts, Washers, Concrete Cylinders, Pile Caps, Blocks, Shims, ETC could be subject to

change per job installation.

All metal components are rust resistant steel and torqued down to meet or exceed building strength requirments.

Each piling could be locked differently depending on material style.

Other Methods We Use:

Concrete Pads

Concrete Piers

Steel Piers

|

CONCRETE PAD

Advantages

1. Quick.

2. Cheap.

Disadvantages

1. Temporary fix.

2. Depth does not reach stable soils.

3. Moves as soil moves.

|

|

|

CONCRETE PIERS

(8 to 12 feet)

Advantages

1.Permanent solution when properly installed.

2.Depth can be verified.

3.Soils can be checked visually.

4.Alignment can be visually verified.

5.Concrete is steel reinforced.

6.A bell can be added to the bottom of the shaft and will significantly increase the bearing capability,

but significantly complicates the installation and therefore reliability.

Disadvantages

1. Soils are not properly identified.

2. Takes 1 to 2 weeks to complete job.

3. Mess of pouring concrete plus time delays can cause expensive loss or damage to plants.

4. Same design for all structures regardless of size or soils.

|

|

|

STEEL PIERS

Advantages

1. Speed and ease of installation.

2. Load can be tested during installation.

3. Steel pipe can be installed at much greater depth.

4. Not as traumatic for vegetation.

Disadvantages

1. Material costs are unnecessarily greater. This cost is passed onto you, the customer.

2. Extensive corrosion of steel pipe in some soils; especially near the surface in disturbed fill soils.

3. The circumference of steel piers is smaller (less than 3”) therefore problems may occur with flex (bow) due to inadequate stiffness.

4. The inherent slenderness of the pier requires that you drive to greater depths to insure adequate skin friction, which creates problems with alignment.

5. Supports the structure indirectly rather than directly as in other methods.

|

Some Other Commonly Used Methods:

Simple Pressed Pilings

Helical Piers

Pressed Piling System With Cable

Piling Lock Copycats

Mud Pumping (Mud Jacking)

Don't let the inexperienced foundation repair companies make your home even worse.

Mud Pumping is a common practice by the inexperienced foundation repair companies.

Mud pumping is a temporary fix that will not last long with the expansive clay soils that we have in our area.

The pictures above are of a home that MSFRS had to perform structural repairs on after another company used the mud pumping method less than a year ago.

Notice the cracks in the home that came back, and the very unattractive pipes left in the ground alost a year later.

Don't let the inexperienced companies work on your home! Call Mississippi Foundation Repair today and we will fix it right the first time!!!

|

SIMPLE PRESSED PILINGS

(Depths limited w/o alignment)

Advantages

1. Depth requirement can be determined by the load of the structure being raised.

2. Soils are tested by driving the pilings into the soils.

3. Concrete is tested under the load it is required to support.

4. Pre-cured/tested concrete enables immediate leveling of the structure. Most jobs are completed in a few days.

5. Site cleanliness and rapid turnaround time, save destruction of valuable vegetation.

|

|

|

HELICAL PIERS

Advantages

1. Can be used for underpinning and retaining wall anchoring.

2. Extensive technical support and engineering case studies.

3. No concrete needed on site.

4. Most jobs are complete in two to three days.

5. Wide variety of mounting brackets and pier shaft diameters, allowing different solutions in residential and commercial applications

Disadvantages

1. Performance is not determined by the capacity of the steel shafts.

2. Extensive corrosion of steel pipe in some soils; especially near the surface in disturbed fill soils.

3. Pier buckling is severe problem. Best performance is limited to stable soils.

4. The load of the structure cannot determine depth requirements.

5. False torque readings in installation notes are common without careful supervision.

6. Prices of steel, equipment, and supervision needed for this system can make it cost prohibitive.

|

|

|

PRESSED PILING SYSTEM WITH CABLE

Advantages

1. All the advantages of simple pressed pilings and steel piers.

2. Custom fitted for your home, with all the guarantees of alignment using the cable.

3. Depth can be verified by measuring the cable extension.

4. The cable has a tensile strength of 200,000 psi versus 40,000 psi rebar used in other systems.

5. The cable controls horizontal movement.

6. The entire pile system is locked together with the cable. This enables the lower portion of the piling to act as an anchor preventing upheaval during wet periods (much like the under-ream on a pier).

7. City inspectors, engineers and you personally can verify job performance.

8. Pilings are tested during installation (concrete and soil) to insure future performance.

9. Safety factor provided by the driving load versus the support load combined with thixotropy insures the pilings future performance.

10. Installs directly under the footer unlike the other systems.

11. It can be installed in interior of home.

Disadvantages

1. Lack of lateral strength for prevention of horizontal movement and proper alignment.

2. During installation, cable may flex causing piling to turn toward least resistance (of soft spots of soils)..

|

|

|

PILING LOCK COPYCATS

Advantages

1. Depth requirement can be determined by the load of the structure being raised.

2. Soils are tested by driving the pilings into the soils.

3. Concrete is tested under the load it is required to support.

4. Pre-cured/tested concrete enables immediate leveling of the structure. Most jobs are completed in a 2-3 days.

5. Site cleanliness and 2-3 day job time, save destruction of valuable vegetation.

6. Prevents horizontal shifting of cylinders.

Disadvantages

1. Proper installation cannot be verified.

2. Alignment is impossible given below ground obstructions.

3. City cannot inspect due to time requirement. Therefore, inspectors must be paid by the company performing the work or not at all.

4. You cannot verify depth.

5. Pilings are not locked together and may tilt with moisture changes.

6. During installation, pilings are not locked together, which can cause misalignment or damage to piling cylinders.

|